In 2012, the Department for Planning, Transport and Infrastructure in South Australia installed 2.3 km of median wire rope safety barrier (MWRSB) along a section of the Victor Harbor Road known locally as Willunga Hill (Dua & Anderson 2013). The section of undivided four-lane/two-way roadway has a steep grade combined with several horizontal curves over a short distance. This section was chosen for treatment as it had experienced a number of fatal and serious crashes due to vehicles crossing over the centreline. The MWRSB is installed in the middle of a 2.0 m wide flush sealed median along with roadside wire rope and W-beam barrier. Audio-tactile edgeline and centreline markings were also installed as part of the project.

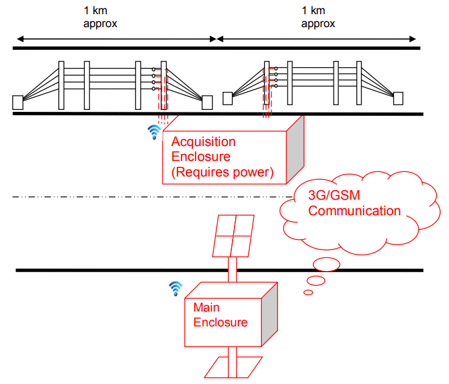

Figure 10.19: Automated measurement of tension in wire rope safety barriers

A novel approach was used to address asset maintenance issues by installing a load cell monitoring system. The system measures the tension of the MWRSB wire ropes and can be monitored via an app on a mobile phone. Maintenance costs have been reduced as the critical condition of the facility can be monitored remotely and crews only sent out when required (Dua & Anderson 2013). Notifications can be triggered when wire tension changes beyond a threshold level possibly indicating a vehicle collision; at this stage, the value of this approach is limited by the close proximity to a load cell in which crashes need to occur to be detected (O’Callaghan 2015). The design of this system nonetheless demonstrates the value of novel approaches for overcoming such practical issues.